In 1271 when Marco Polo left Venice at the start of his journey to the land of the Kublai Khan, there was another Marco that traveled with the expedition.

Rope Making

[The art of twisting, long before Chubby Checker]

Next to their flint tipped spears and stone tools, the art of rope making must surely have been one of the oldest crafts practiced by prehistoric man.

Initially ‘ropes’ were probably simple strands of long grass or lianas and vines. Twisting these strands together and braiding them produced longer and stronger ropes. Evidence of these early ropes has been found on fired clay dating back 28,000 years. Further evidence of fossilized rope fragments found in the Lascaux caves has been dated to be 17,000 years old.

In ancient Egypt, over 3500 years ago, rope was made from papyrus reeds with special rope making tools. Without these ropes it would have been impossible to undertake the massive building projects that Egypt is known for. China is another source of the earliest rope making ‘factories’. Needless to say, this essential craft soon spread to Europe and beyond.

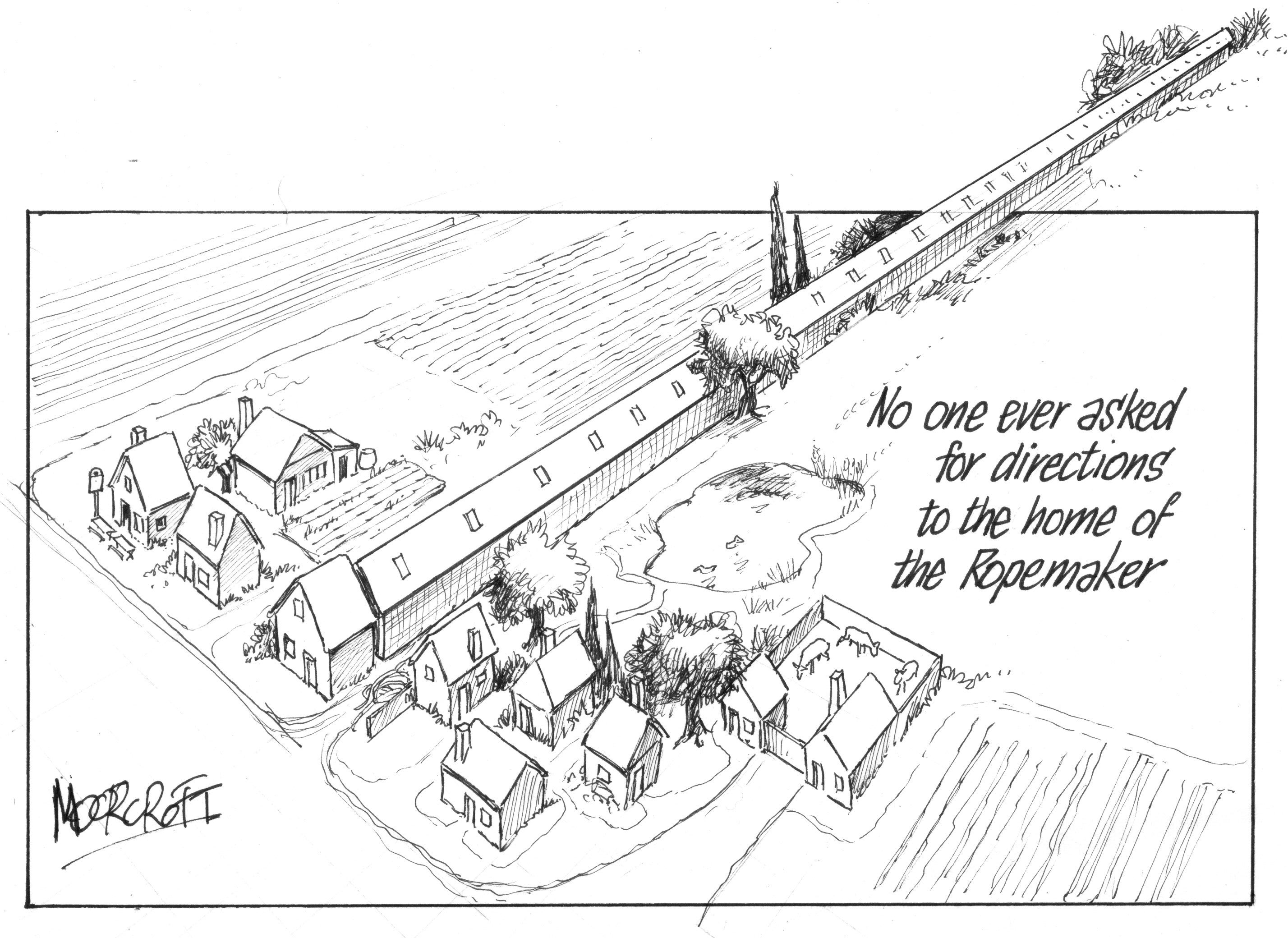

The Middle Ages saw long buildings being erected all over Europe called ‘ropewalks’ in which ropes were manufactured. The length of the ropewalk was the maximum length of the rope being ‘laid up’ or twisted together.

As ships became bigger and taller, the need for longer and longer rope became essential. Some shorter ropes could be made longer by splicing them together. Unhappily, this spliced area would become fatter, and as most ropes on the big ships had to pass through pulleys or blocks, they jammed. It was therefore imperative that rope makers built longer and longer ropewalks!

Modern rope manufacturing of course, no longer needs a stretched building to produce rope.

No matter which raw material is used to make rope, it must be twisted together [possibly spun on a spinning wheel] to make a thin yarn [also known as string or twine]. I could never understand how the very short segments of wool, or cotton or the hair of Angora rabbits could be twisted [spun] into long lengths of yarn without them untangling themselves when the twisting stopped and falling apart on the ‘take-up’ bobbins or sticks they were being wound onto. So, I looked at a few videos on spinning and was amazed how handfuls of rabbit fur attached themselves to a turning line and to the fur already spinning there.

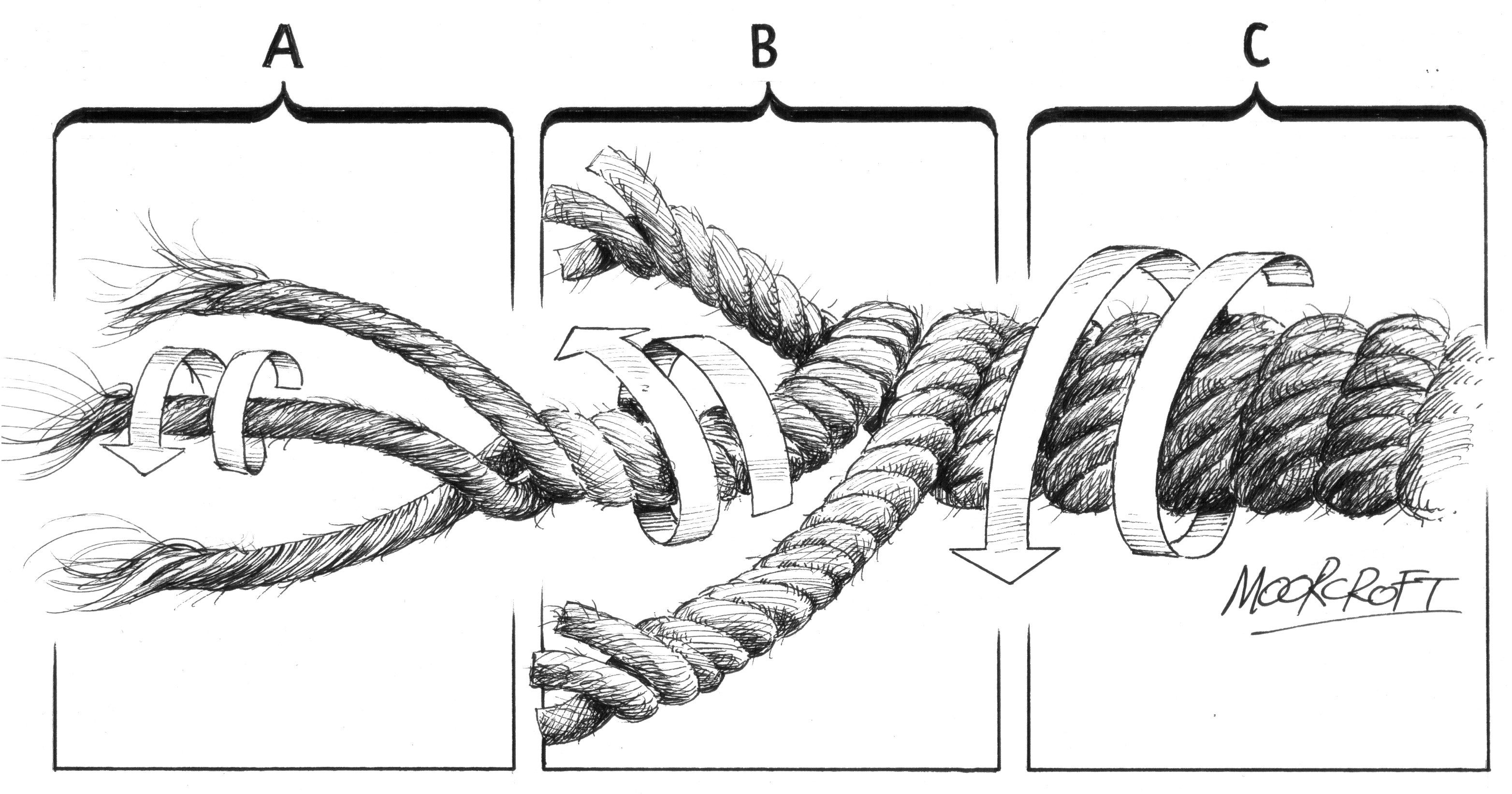

At last I knew how the yarns are made in the first step of traditional twisted rope making. These yarns are then formed into thicker strands by twisting them together. Three strands are then twisted together to lay the rope

YARN STRANDS ROPE

This counter-twist, introduced with each successive process, holds the rope together in it’s combined final form and evenly shares the tension in the individual strands.

Common twisted rope generally consists of three strands and can be twisted to the right or to the left. The middle section of the uppercase letters S and Z show the slant of the twist to the right or to the left. as they move away from the onlooker. Thus Z-twist rope specifies a right-handed twist, and S-twist is a left-handed twist.

Twisted ropes have a preferred direction for coiling. Normal right-laid rope should be coiled clockwise, to prevent kinking.

Since 1950, synthetic fibres such as polypropylene and nylon, began to replace natural fibres as the preferred rope making material. Synthetic fibre ropes are not only much stronger than natural fibres, they also do not rot when stored in damp conditions.

Rope is also made from steel wire.

It is interesting to note that rope changes its name, depending on the task or function assigned to it. On sailing ships, ropes that pull sails up the mast are called halyards and ropes that control these sails at deck level are called sheets. The thick rope that holds the anchor is called a rode. We think of a clothes line not a clothes rope and catch fish with a fishing line, not a fishing rope.

Rope has been used for thousands of years and will continue to assist man for thousands of years into the future.